What is ALIN?

A next-generation waste treatment solution that converts organic matter into energy and resources

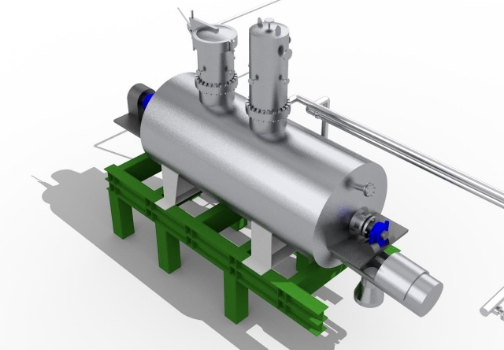

Features of ALIN-box

ALIN-box is a compact treatment device that efficiently decomposes waste using subcritical water treatment technology. It deodorizes and neutralizes organic waste such as household waste, food waste, and medical waste, ensuring a rapid and environmentally friendly process. Its size makes it suitable for installation in locations where waste is generated regularly, such as apartments, schools, and small facilities, with the additional benefit of easy operation.

Subcritical Water Treatment Technology

ALIN-box decomposes waste under subcritical water conditions of 200 degrees Celsius and 20 MPa. This technology allows waste to be processed at a molecular level without incineration, resulting in rapid depolymerization. Unlike traditional incineration methods, there is no generation of greenhouse gasses, and odor issues are also minimized.

Processing Time and Efficiency

ALIN-box can process waste in approximately 2 hours. It can handle various types of waste, significantly reducing the processes and time required compared to the conventional incineration or fermentation methods, which contributes to immediate deodorization and neutralization of waste.

Flexible Response from Small to Large Scale Processing

By adjusting the processing capacity of the equipment and the design of plant facilities, ALIN can accommodate a wide range of installations from single apartments, buildings, and schools to large-scale waste treatment facilities.

Environmental Contribution

The residues generated during the decomposition process can be utilized as energy or compost, significantly reducing CO2 emissions from incineration. This contributes to the construction of a society with a recycling-oriented system.

Performance of ALIN

ALIN is a waste treatment device designed for urban and industrial facilities. In addition to waste decomposition, it incorporates a methane fermentation plant to utilize the residues for biogas power generation. The energy generated can be used within the facility or can be sold externally, creating economic benefits.

Processing Capacity

ALIN allows a wide selection of appropriate equipment based on the waste processing volume, including ALIN3, ALIN5, and ALIN10. By performing hydrolysis without burning waste, it minimizes CO2 emissions, achieving environmentally friendly processing.

Biogas Power Generation

Organic material remaining after waste processing is fermented in a methane digester, generating clean biogas. This gas is used to produce electricity (biogas power generation). The generated energy can be utilized for the facility’s power supply or sold externally.

Cost Efficiency and Economic Viability

Compared to traditional incineration facilities, ALIN significantly reduces initial costs (installation costs). Additionally, by utilizing the residues for energy and other purposes, the overall financial performance of the plant equipment can be improved compared to that of the conventional treatment facilities.

Long Lifespan and Easy Maintenance

ALIN operates at a low temperature (200 degrees Celsius), eliminating the need for maintaining high-temperature furnaces and heat-resistant materials that are typical to conventional incineration facilities. It has a long lifespan of over 50 years and is designed to incur minimal maintenance costs. Process for regular maintenance is also straightforward, leading to lower operational costs compared to traditional waste incineration plants.