ALIN Technology and

Methane Fermentation/Biogas Power Generation

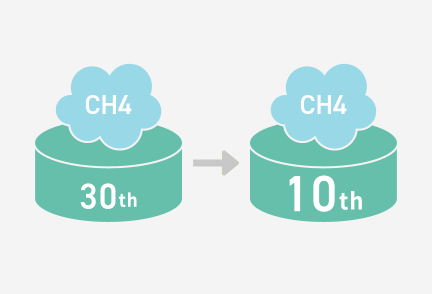

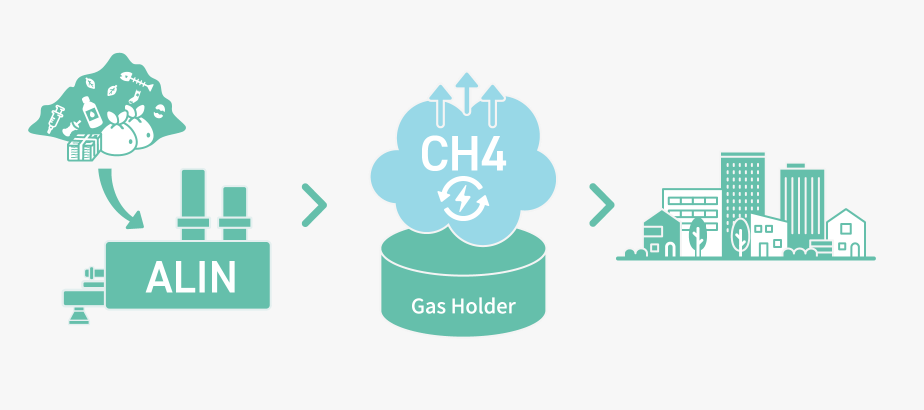

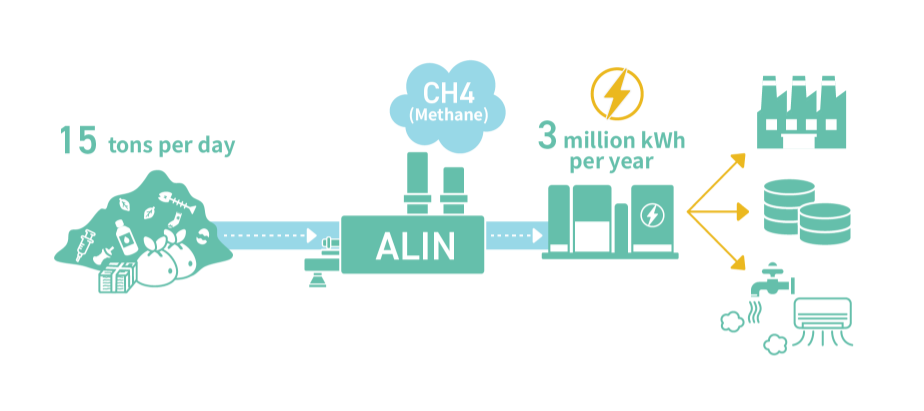

ALIN technology significantly enhances methane fermentation and biogas power generation. By treating the raw materials with subcritical water, the fermentation process, which typically takes over 30 days, can be shortened to approximately 10 days, allowing an efficient generating process of clean energy. Additionally, the amount of biogas produced will be increased, which can be utilized for power generation and thermal energy, realizing more advanced energy utilization.

Improvement of Fermentation Speed

Using ALIN technology (subcritical water treatment), the time required for methane gas fermentation, which usually exceeds 30 days, can be reduced to around 10 days.

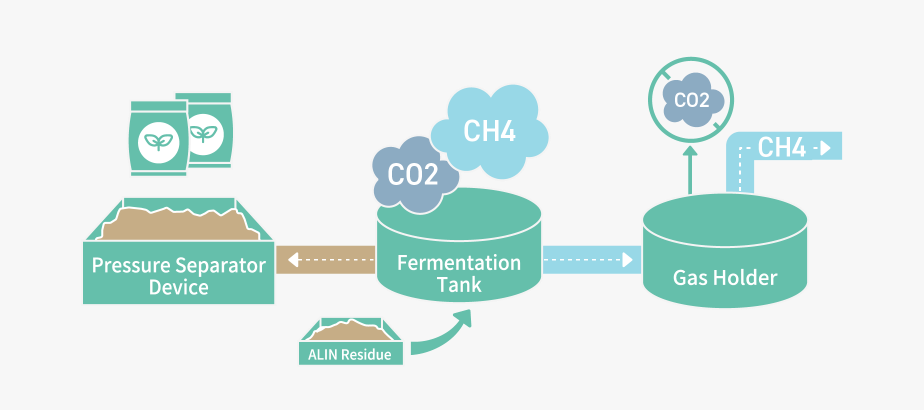

Increase in Biogas Production

With the introduction of ALIN, the amount of biogas it can generated will be approximately 1.8 times that of a typical biogas power generation facility, leading to an increase in revenue opportunity.

Environmental Impact and Sustainability

Compared to traditional fermentation processes, CO2 emissions are reduced, resulting in higher purity levels of methane gas. Furthermore, the digested liquid remaining after fermentation can be reused as compost, achieving an environmentally friendly circulation process.

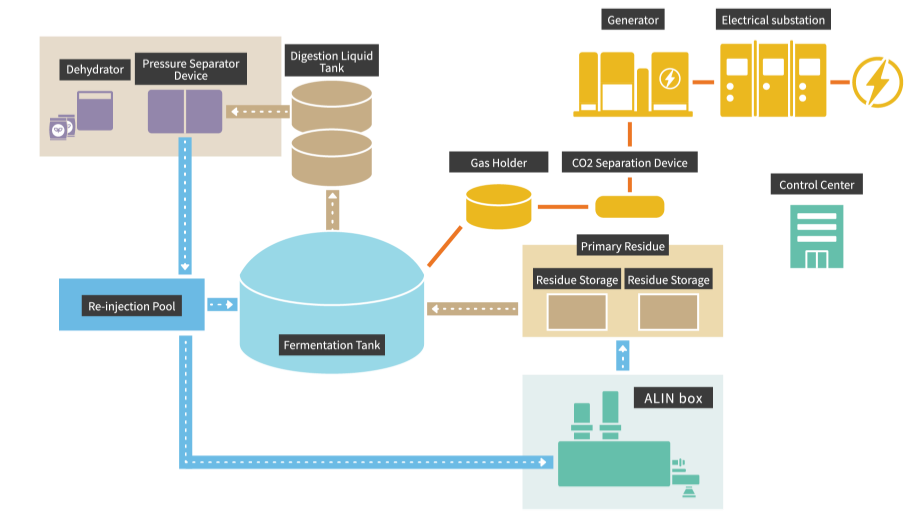

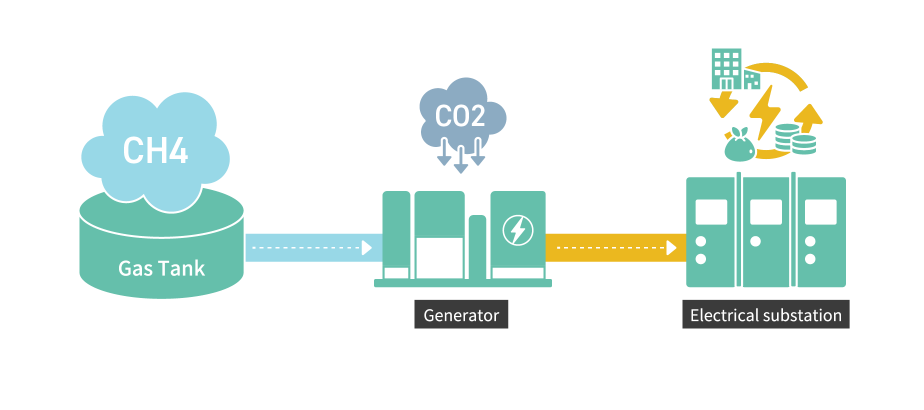

Mechanism of Biogas Power Generation

Biogas power generation utilizes biogas (primarily methane gas) which are produced through methane fermentation, converting energy into electricity and thermal energy for generators. Biogas is a clean energy source produced during the decomposition of organic matter and is one of the forms of renewable energy.

Biogas power generation yields renewable energy derived from waste treatment, with power generation quantities varying according to the facility size. Particularly in large-scale waste treatment facilities, significant amounts of biogas are generated through methane fermentation, resulting in substantial electricity production.

As a clean and sustainable energy source, biogas power generation can significantly reduces environmental impact. By reutilizing waste as an energy source, it greatly lowers CO2 emissions compared to the traditional waste treatment methods.

Comparison with Other Treatment Methods